Heave Stopper

Clay Heave & Ground Recovery

Slide title

Write your caption hereButton

Heave Stopper - Forming a True Void

Heave Stopper FAQ

-

What is anti heave protection?

Heave Stopper is used to protect against clay and ground heave, typically on the inside of piled ground beams or deep trench fill foundatios.

Ground beams, slabs and concrete foundations can be subject to cracking as a result of the forces of ground movement when built on areas of shrinkable soil. These areas include clay, expansive shale soils, reclaimed land or ground recovery caused by deep excavations.

The structural damage caused by clay is acknowledged by engineers and

designers all over the world. In the U.K the problem is particularly acute in the South East, although climate change is having its effect on soils in other parts of the country.

The solution is to create a void below concrete foundations, allowing unhindered expansion of clay

-

What are heave boards?

The Heave Stopper baord is an eco-friendly, recycled construction void former that protects against ground movement whilst laying concrete foundations.

The closed cell structure means that Heave Stopper can be trimmed tightly around the pile heads and service ducts without losing the integrity of the panel.

It is used to create a void underneath the foundation for

ultimate stability in ground liable to ground heave.

Heave Stopper has a high strength to weight ratio. When the honeycomb core is introduced to water it is designed to lose it’s strength in order to permit ground heave without

transmitting pressure to the foundations or structures above.

Heave Stopper can be installed either side up. It can be easily cut with hand tools and the joints do not need to be taped together with no requirement to tape the joints.

Heave Stopper is light and easy to use, Heave Stopper can be installed at a rate of 50m2 per hour or more, by one person.

-

How do you stop ground heaves?

Where heave is likely to be a problem, Heave Stopper should be installed beneath foundations and floor slabs to reduce the upward force of heave from transmitting to the structure above.

Heave Stopper is suitable for beams & slabs. Also a perfect solution for contaminated land and brownfield sites.

-

Can Heave Stopper be used when wet

No. Heaver Stopper cannot be used when wet.

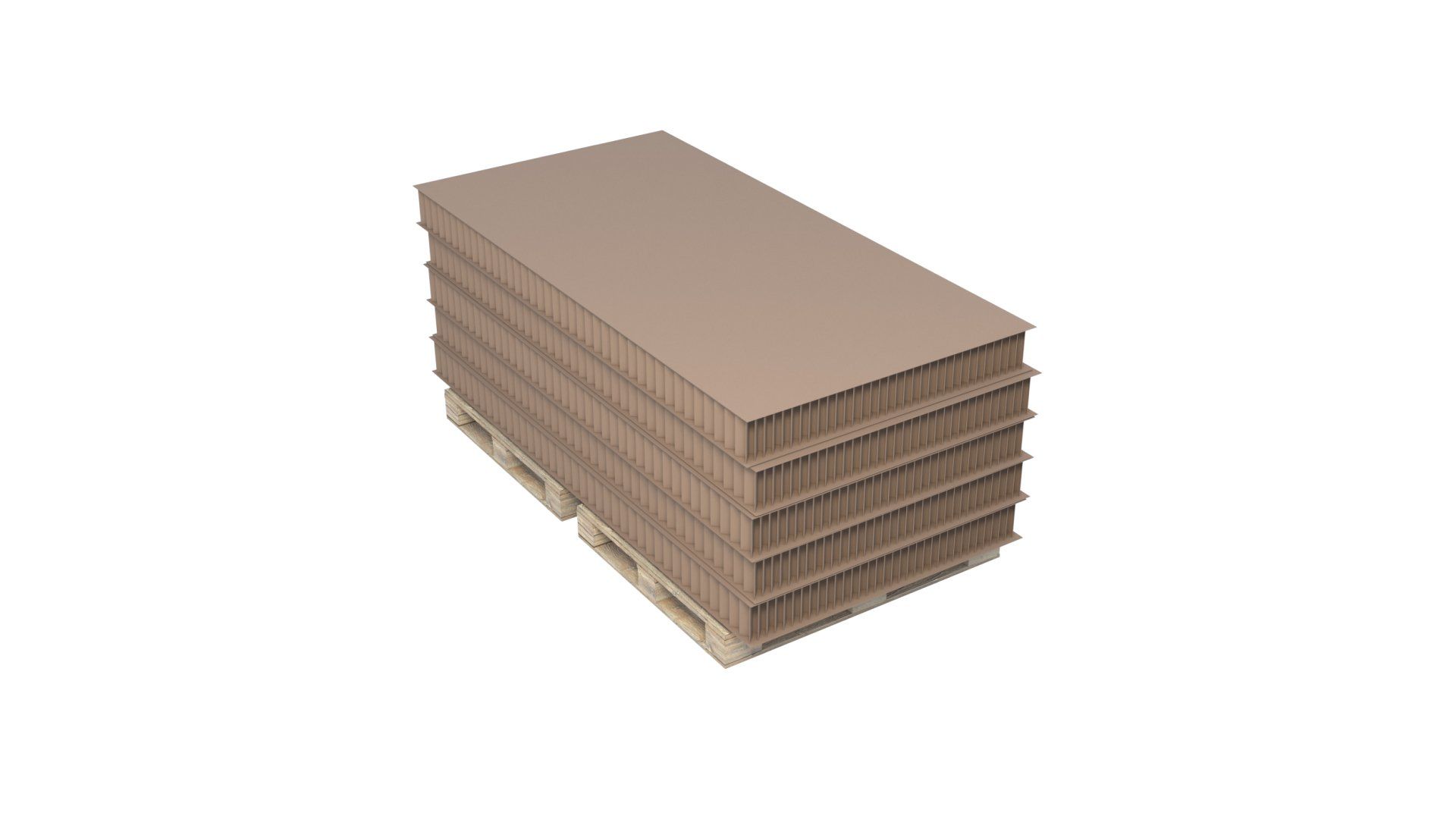

The boards must be kept dry, stored off the ground and on the delivery pallets to prevent any moisture ingress whilst in storage.

Heave Stopper is also available packaged in a Water Tight 500g Polythene bag to protect the board against natural elements.

Please note that the boards will need to be removed from the Polythene bags prior to the concrete being poured.